As an equipment owner, you understand the importance of keeping machinery well-maintained. One of the most critical components in this process is ensuring that grease fittings are clean and free from contaminants. However, cleaning these fittings can be a time-consuming and challenging task.

Fortunately, there’s a solution to this problem: a grease fitting cleaning tool. In this article, we’ll discuss everything you need to know about these tools and how they can benefit your maintenance routine.

What is a Grease Fitting Cleaning Tool?

A grease fitting cleaning tool is a specialized device designed to remove dirt, debris, and other contaminants from grease fittings. These tools come in various shapes and sizes but typically feature a handle with a metal tip that fits into the grease fitting.

The tool’s unique design allows it to force out any obstructions within the fitting, allowing fresh grease to flow freely through the system. This simple yet effective tool can save hours of maintenance time and ensure that your equipment runs smoothly.

Why Use a Grease Fitting Cleaning Tool?

Cleaning grease fittings manually can be almost impossible in some cases. Often the fittings are located in hard-to-reach areas or are covered in grime and dirt, making them difficult to access. In such scenarios, using a grease fitting cleaning tool becomes essential as it provides an efficient solution.

Using a grease fitting cleaning tool has several advantages over manual cleaning methods:

1. Time-Saving

Cleaning grease fittings manually can take hours depending on the number of fittings present on your equipment. A cleaning tool simplifies the process by quickly removing any contamination without wasting time.

2. Improved Equipment Performance

By regularly cleaning your equipment’s grease fittings with a cleaning tool, you’re ensuring that fresh grease flows freely through the system. This helps maintain optimal performance levels and extends the lifespan of your machinery.

3. Reduced Maintenance Costs

Regular maintenance of your equipment is vital, but it can also be expensive. By using a grease fitting cleaning tool, you’re reducing the frequency of maintenance needed and saving on costs in the long run.

4. Easy to Use

A grease fitting cleaning tool is easy to use, making it ideal for both novice and experienced equipment owners. The tool’s design allows for quick and efficient cleaning, which means less time spent on maintenance.

How to Use a Grease Fitting Cleaning Tool

Using a grease fitting cleaning tool is straightforward. Follow these simple steps to ensure that your fittings are clean and free from contamination:

Step 1: Identify the grease fittings that require cleaning.

Step 2: Choose an appropriate sized cleaning tool that fits into the grease fitting.

Step 3: Insert the metal tip of the cleaning tool into the grease fitting.

Step 4: Push the handle of the cleaning tool firmly until you feel resistance.

Step 5: Rotate the handle back and forth several times while maintaining pressure on the metal tip.

Step 6: Remove the cleaning tool from the grease fitting and wipe away any excess dirt or debris.

Repeat this process for each of your equipment’s grease fittings until all are clean. It’s recommended to perform this task regularly to maintain optimal performance levels.

Types of Grease Fitting Cleaning Tools

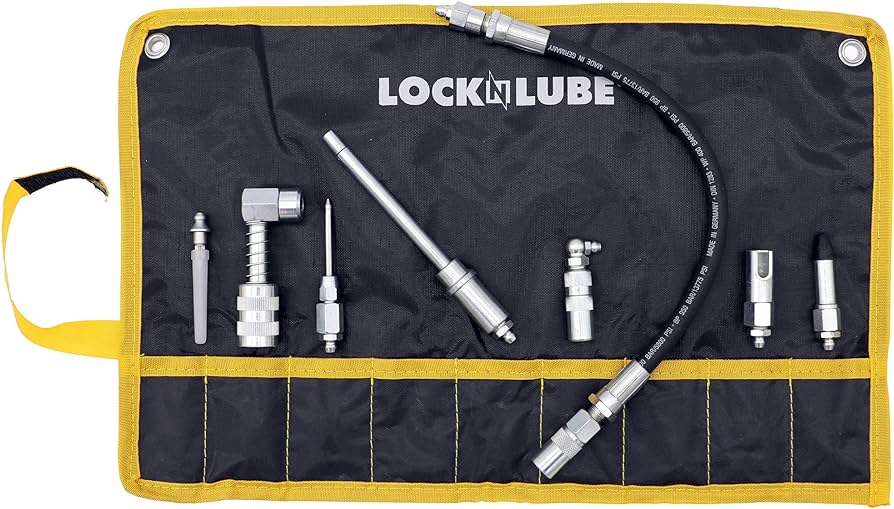

Grease fitting cleaning tools come in various shapes and sizes, each designed to suit different machinery types and models. Some of the most common types include:

1. Needle-Type Cleaning Tools

These tools feature a long, thin needle-like tip that can reach deep into hard-to-reach places, making them ideal for small and intricate machinery.

2. Button-Head Type Cleaning Tools

These tools have a button-shaped head with a flat side that fits snugly against the face of the fitting. They’re best suited for fittings with large openings.

3. Multi-Purpose Cleaning Tools

As their name suggests, multi-purpose cleaning tools are versatile and can be used on various types of machinery. They typically feature interchangeable tips and come with multiple attachments to suit different fittings.

Conclusion

A grease fitting cleaning tool is an essential tool for any equipment owner looking to maintain their machinery’s optimal performance levels. By using this simple but effective tool, you can save time and money while ensuring that your equipment runs smoothly.

Remember to choose the right cleaning tool for your machinery type and regularly inspect and clean your equipment’s grease fittings. Doing so will help you avoid costly repairs and extend the lifespan of your equipment.

References:

1. https://en.wikipedia.org/wiki/Grease_fitting

2. https://www.machinerylubrication.com/Read/30353/grease-fitting-cleaning