In the world of manufacturing, precision is key. To achieve accuracy and efficiency in machining processes, professionals rely on high-quality tools that can deliver consistent results. When it comes to cutting-edge solutions for precision machining and beyond, Komet Tools stands out as a leader in the industry.

Founded in Germany in 1918, Komet Tools has a long history of innovation and excellence in tool manufacturing. Today, the company offers a wide range of cutting tools, including drills, reamers, milling cutters, and more. With a focus on quality, reliability, and performance, Komet Tools has become a trusted partner for businesses around the world.

In this article, we’ll explore what makes Komet Tools stand out from the competition and how these tools can help you achieve your machining goals.

Why Choose Komet Tools?

There are several reasons why Komet Tools is a top choice for machinists and manufacturers worldwide. Here are just a few of the key benefits:

Precision: Komet Tools are engineered with precision in mind. From design to production, every step is carefully crafted to ensure accuracy and consistency.

Durability: Made with high-quality materials and advanced manufacturing techniques, Komet Tools are built to last. They can withstand even the toughest machining conditions without losing their edge.

Versatility: Whether you’re working with metal, wood, or other materials, Komet Tools offer a wide range of options to meet your needs. With various sizes, shapes, and coatings available, you can find the perfect tool for any job.

Innovation: As a leader in the industry, Komet Tools is constantly pushing the boundaries of what’s possible in machining technology. From new materials to advanced designs, they’re always looking for ways to improve their products and stay ahead of the curve.

Types of Komet Tools

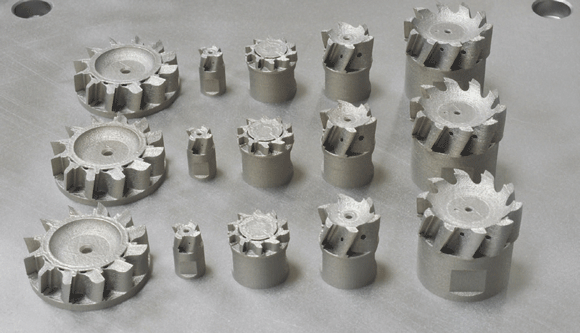

Komet Tools offers a wide range of cutting tools for various applications. Here are some of the most popular types:

Drills: Komet Tools offers a variety of drill options, including solid carbide drills, indexable insert drills, and more. With features like internal cooling and optimized chip evacuation, these drills can deliver precise results even in challenging materials.

Reamers: For precision sizing and finishing, Komet Tools reamers are an excellent choice. Available in both solid carbide and indexable formats, these tools can help you achieve tight tolerances and smooth finishes.

Milling Cutters: From roughing to finishing, Komet Tools milling cutters offer a range of options for different applications. With advanced coatings and designs, these cutters can help increase productivity and reduce tool wear.

Boring Tools: Komet Tools boring tools are designed to deliver accuracy and efficiency in hole-making operations. Whether you need a single-point boring bar or a multi-edge tool, they have options to suit your needs.

In addition to these core products, Komet Tools also offers specialty tools for specific applications. For example, their line of aerospace tools is designed specifically for the demands of that industry. They also offer custom tool solutions for unique machining challenges.

Using Komet Tools

To get the most out of your Komet Tools, it’s important to follow best practices for use and maintenance. Here are some tips:

Select the right tool for the job: With so many options available, it’s essential to choose the right tool for the task at hand. Consider factors like material type, cutting speed, and depth of cut when making your selection.

Use proper cutting parameters: Once you’ve selected your tool, be sure to use the correct cutting parameters for optimal performance. This includes factors like spindle speed, feed rate, and coolant flow.

Monitor tool wear: Over time, all cutting tools will experience wear and tear. By monitoring your Komet Tools regularly, you can detect signs of wear and replace them before they fail.

Perform regular maintenance: To keep your tools in top condition, be sure to perform regular maintenance tasks like cleaning, lubricating, and sharpening as needed.

By following these guidelines, you can maximize the lifespan and performance of your Komet Tools.

Conclusion

When it comes to precision machining and beyond, Komet Tools is a top choice for professionals around the world. With a focus on quality, durability, and innovation, these cutting-edge tools can help you achieve your machining goals with ease. Whether you’re working with metal, wood, or other materials, there’s a Komet Tool that’s perfect for the job.

If you’re interested in learning more about Komet Tools and how they can benefit your business, be sure to visit their website or contact a representative today.

References:

– Komet Group. (n.d.). About Us. Retrieved from https://www.kometgroup.com/en-us/about-komet-group/

– Komet Group. (n.d.). Products. Retrieved from https://www.kometgroup.com/en-us/products/

– Sandvik Coromant. (2018). Machining Solutions for Aerospace. Retrieved from https://www.sandvik.coromant.com/en-us/solutions/aerospace/Pages/default.aspx