Are you tired of constantly guessing which air tool to use for a specific job? Do you want to maximize your tool’s performance and efficiency? Look no further than the air tool CFM chart! In this article, we’ll guide you through everything you need to know about using an air tool CFM chart to make informed decisions and achieve optimal results.

What is an Air Tool CFM Chart?

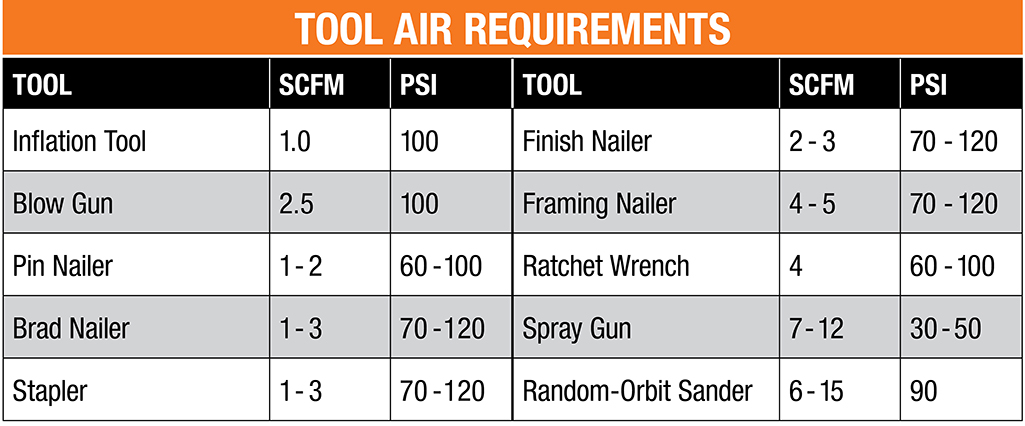

An air tool CFM chart is a tool that helps determine the amount of compressed air needed to power a particular air tool. CFM stands for cubic feet per minute, which is a measure of how much air a compressor can deliver at a given time. Each air tool requires a certain amount of CFM to operate correctly, and exceeding or falling short of this requirement can result in reduced performance or even damage to the tool.

Why Use an Air Tool CFM Chart?

Using an air tool without considering its required CFM can result in wasted time, money, and energy. If you overestimate the required CFM, you may end up using more compressed air than necessary, resulting in higher energy costs. Conversely, if you underestimate the required CFM, your tools won’t be able to function at their best capacity.

By using an air tool CFM chart, you can ensure that you’re using the right amount of compressed air for each tool, improving efficiency and prolonging the life of your equipment. Additionally, using an air tool CFM chart allows you to compare different tools’ requirements, helping you make informed purchasing decisions based on your needs.

How to Read an Air Tool CFM Chart

Reading an air tool CFM chart may seem daunting at first glance, but it’s relatively straightforward once you understand its components. Most charts are divided into two sections: one for single-tool operation and another for multiple-tool operation.

Single-Tool Operation

The single-tool operation section of the air tool CFM chart lists each air tool, along with its required CFM at various PSI levels. To use this section, simply locate your tool and find its CFM requirement at the PSI level you plan to use it. Make sure that your compressor can deliver the amount of compressed air necessary for your tool.

Multiple-Tool Operation

The multiple-tool operation section of the air tool CFM chart is more complex but still easy to use. It lists different combinations of tools, along with their total required CFM at various PSI levels. For example, if you plan to use a spray gun and an impact wrench simultaneously, find these tools on the chart and add their required CFMs together to get the total CFM needed for both tools.

Once you have determined the total required CFM for all your tools, make sure that your compressor can deliver that amount of compressed air. If not, consider upgrading your compressor or adjusting your tool usage accordingly.

Factors Affecting Air Tool CFM Requirements

Several factors can affect an air tool’s required CFM, including:

– Tool size: Larger tools typically require more compressed air than smaller ones.

– Operating pressure: Tools used at higher PSI levels require more compressed air than those used at lower levels.

– Usage frequency: Tools used frequently may require more compressed air than those used occasionally.

– Tool type: Different types of tools (e.g., sanders vs. drills) have varying CFM requirements.

It’s essential to consider these factors when using an air tool CFM chart to ensure that you’re making accurate calculations and using the right amount of compressed air for each job.

Conclusion

Using an air tool CFM chart may seem intimidating at first, but it’s a valuable tool for anyone who uses power tools regularly. By understanding how to read and interpret an air tool CFM chart, you can optimize your tool’s performance, prolong its lifespan, and save time, money, and energy in the long run.

Remember to consider the various factors that can affect an air tool’s required CFM when using a chart, and always make sure that your compressor can deliver the necessary amount of compressed air. With these tips in mind, you’ll be well on your way to becoming a power tool pro!

References:

– “CFM Chart for Air Compressors.” Quincy Compressor. https://www.quincycompressor.com/cfm-chart-for-air-compressors/

– “Air Tool CFM Requirements.” Air Compressor Guide. https://www.air-compressor-guide.com/air-tool-cfm-requirements.html

– “Air Tool CFM Chart: How to Choose the Right Air Compressor.” Pro Tool Reviews. https://www.protoolreviews.com/buying-guides/how-to-choose-the-right-air-compressor/42048/

Hyperlinks:

– Quincy Compressor – https://www.quincycompressor.com/

– Air Compressor Guide – https://www.air-compressor-guide.com/

– Pro Tool Reviews – https://www.protoolreviews.com/