Belts are an integral part of many machines and equipment, making them operate smoothly and efficiently. However, misaligned belts can cause serious problems, including wear and tear, reduced performance, and even downtime. That’s where belt alignment tools come in handy. In this article, we’ll explore everything you need to know about belt alignment tools, how they work, their benefits, and more.

What Is a Belt Alignment Tool?

A belt alignment tool is a device used to ensure that the belts on machinery are correctly aligned. These tools are designed to detect any misalignment between the pulleys and adjust them accordingly. Belt alignment tools come in different shapes and sizes, but they all serve the same purpose: to improve the efficiency and performance of your machines.

How Does It Work?

Belt alignment tools use lasers or sensors to detect any misalignment between the pulleys. They project a laser beam onto the belt’s surface and measure the distance from the centerline of one pulley to another. Based on this measurement, the tool will indicate whether or not the belt is properly aligned.

If there is a misalignment, the belt alignment tool will guide you through the process of adjusting it. Some tools have a built-in display that shows you exactly how much adjustment is needed in real-time. This feature makes it easy for operators to make quick adjustments without having to stop the machine.

Benefits of Using a Belt Alignment Tool

1. Increased Efficiency

One of the most significant benefits of using a belt alignment tool is increased efficiency. When belts are correctly aligned, they run smoothly and with less friction. This means they require less energy to operate, which ultimately leads to lower energy costs.

2. Reduced Wear and Tear

Misaligned belts can cause excessive wear and tear on both the belts and pulleys. Over time, this can result in premature failure and costly repairs. By using a belt alignment tool, you can extend the life of your belts and pulleys and avoid these issues.

3. Improved Performance

Properly aligned belts also mean improved performance. When belts are misaligned, they can cause vibrations that lead to decreased accuracy and precision. This can be especially problematic for machines that require high levels of accuracy, such as those used in manufacturing or medical applications.

4. Easy to Use

Belt alignment tools are easy to use and require little training. Most tools come with step-by-step instructions, making it simple for operators to adjust the belts themselves. This means less downtime and increased productivity.

5. Cost-Effective

While belt alignment tools may seem like an unnecessary expense, they can actually save you money in the long run. By improving efficiency, reducing wear and tear, and increasing performance, you’ll ultimately save on energy costs and avoid expensive repairs.

Types of Belt Alignment Tools

1. Laser Belt Alignment Tool

Laser belt alignment tools use lasers to project a straight line onto the belt’s surface. The operator then adjusts the pulleys until the laser is centered on both pulleys. These tools are incredibly accurate and provide real-time feedback.

2. Sensor Belt Alignment Tool

Sensor belt alignment tools use sensors to measure the distance between the pulleys. They then display this information on a screen, allowing operators to make adjustments as necessary.

3. Dial Indicator Belt Alignment Tool

Dial indicator belt alignment tools use a dial gauge to measure any misalignment between the pulleys. The operator adjusts the pulleys until the dial gauge reads zero.

4. String Belt Alignment Tool

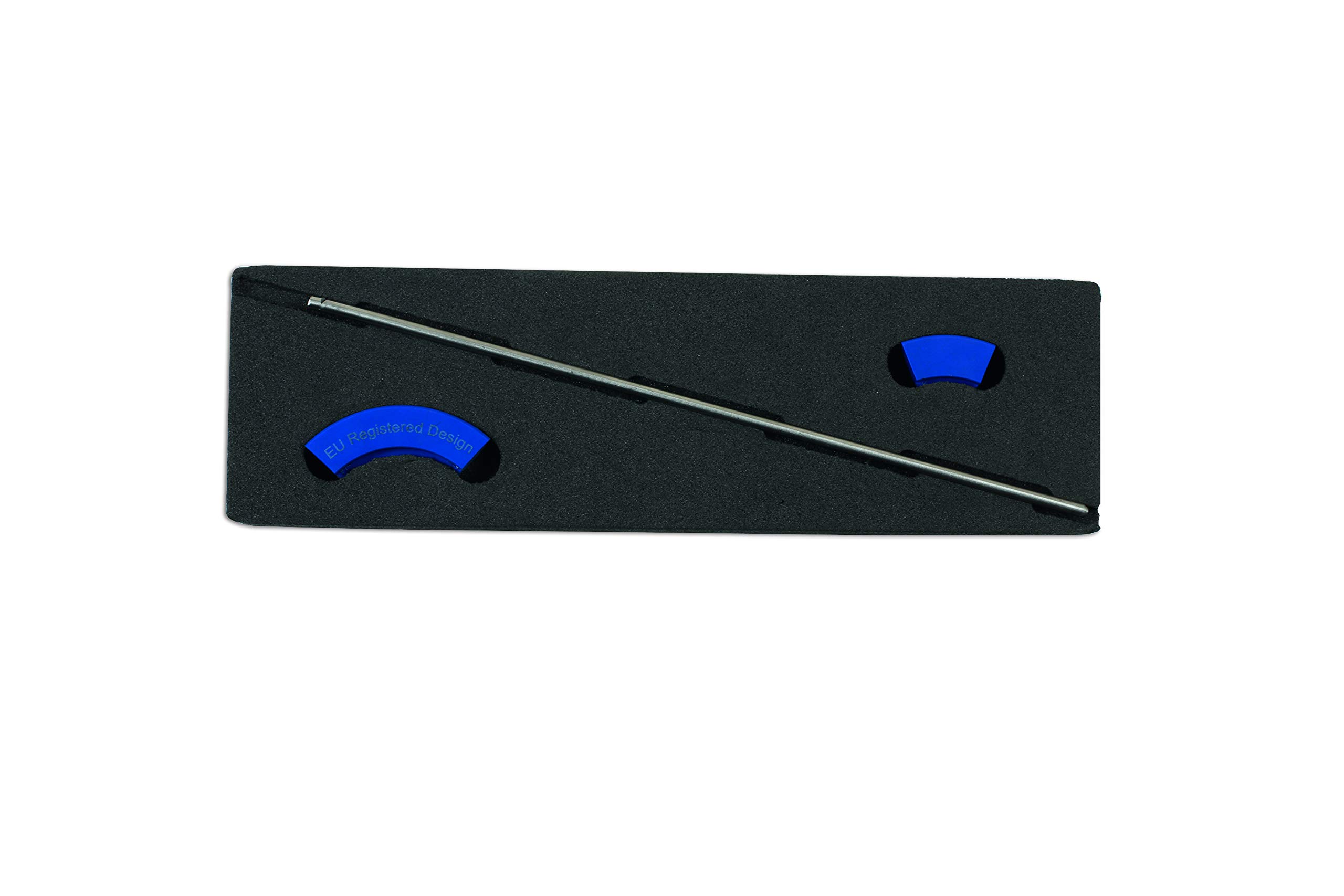

String belt alignment tools use a string or wire to align the pulleys manually. While not as accurate as other methods, they are still effective at improving belt alignment.

Conclusion

Belt alignment is crucial for maintaining efficient machine operation and avoiding costly repairs down the line. Belt alignment tools are an easy and cost-effective way to ensure your belts are properly aligned and operating at peak performance. Whether you choose a laser tool, sensor tool, dial indicator tool, or string tool, using a belt alignment tool is a smart investment that will pay off in the long run.

References:

1. https://en.wikipedia.org/wiki/Belt_alignment

2. https://www.reliableplant.com/Read/30357/belt-alignment-methods

3. https://www.machinerylubrication.com/Read/30745/belt-alignment-basics