Are you tired of dealing with rough edges and burrs in your machining processes? Look no further than the Cogsdill deburring tool. This innovative tool provides a precise and efficient solution to all of your deburring needs.

What is a Cogsdill Deburring Tool?

A Cogsdill deburring tool is a specialized cutting tool designed to remove unwanted material from the surface of a workpiece. It is commonly used in metalworking, plastics, and other manufacturing industries to smooth out rough edges, remove burrs, and improve the overall quality of machined parts.

The Benefits of Using a Cogsdill Deburring Tool

1. Increased Efficiency – A Cogsdill deburring tool can significantly reduce the time it takes to complete deburring tasks. Traditional manual methods are often time-consuming and require a high level of skill and experience. With the Cogsdill deburring tool, you can achieve precision results quickly and easily.

2. Improved Quality – Deburring is an essential step in the manufacturing process as it ensures that parts meet the required specifications for fit, form, and function. A Cogsdill deburring tool eliminates burrs and sharp edges that can cause damage or malfunction in finished products.

3. Cost-Effective – The use of a Cogsdill deburring tool eliminates the need for expensive secondary operations such as hand filing or sanding. This saves both time and money while increasing productivity.

4. Versatility – The Cogsdill deburring tool can be used on a wide range of materials, including metals, plastics, ceramics, composites, and more.

How Does a Cogsdill Deburring Tool Work?

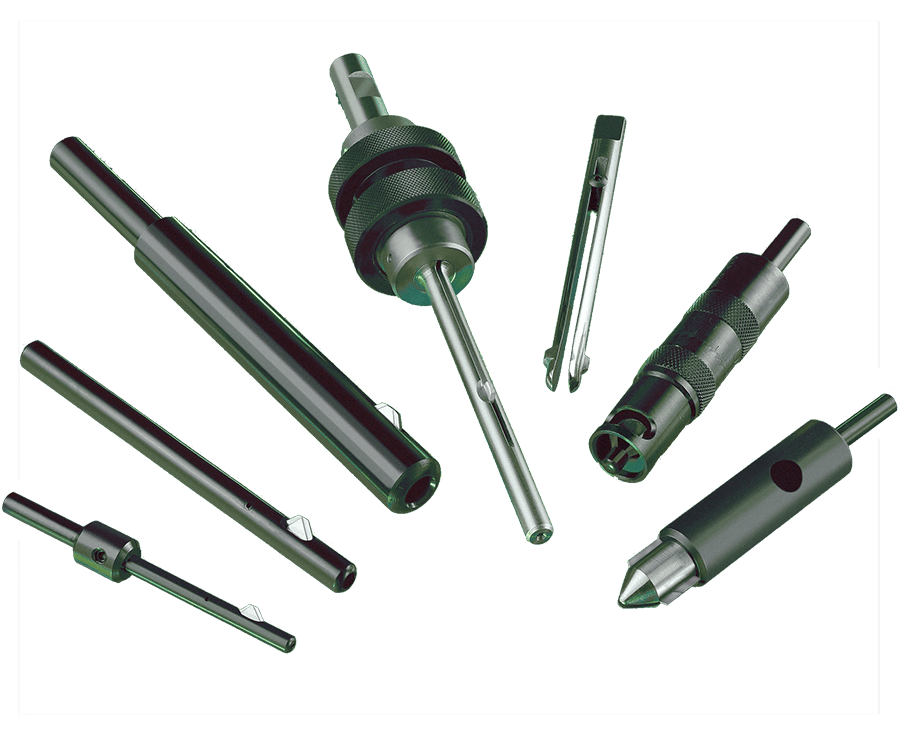

Cogsdill deburring tools come in various shapes and sizes to suit different applications. They generally consist of a cutting head with multiple blades that rotate around a central axis. The blades remove material as they pass over the surface of the workpiece, leaving a smooth and even finish.

The cutting head is typically mounted on a mandrel or arbor that connects to a power source such as a drill press or lathe. The speed and feed rate of the tool can be adjusted to achieve optimal results based on the material being deburred.

Types of Cogsdill Deburring Tools

1. Burr-Zit – The Burr-Zit is a versatile tool designed for use on drilled, punched, or reamed holes. It features replaceable carbide blades that can be easily adjusted for different hole sizes.

2. Micro Roller Burnishing Tool – This tool is used for micro-deburring of small parts with tight tolerances. It features fine-grained abrasive rollers that gently polish the surface of the workpiece.

3. Flex-Hone – The Flex-Hone is a flexible honing tool used for deburring, edge blending, and surface finishing. It consists of abrasive globules attached to flexible nylon filaments that conform to the shape of the workpiece.

4. Speedy-Prep – The Speedy-Prep is an automated deburring system that uses abrasive brushes to remove burrs from complex geometries and hard-to-reach areas.

Using a Cogsdill Deburring Tool Safely

Like all cutting tools, Cogsdill deburring tools must be used safely to avoid injury or damage to equipment. Some safety tips to keep in mind when using these tools include:

1. Wear appropriate personal protective equipment such as safety glasses, gloves, and ear protection.

2. Ensure that the tool is securely mounted and aligned before starting it.

3. Follow recommended speed and feed rates for optimal performance.

4. Avoid excessive pressure or force when using the tool, as this can cause damage or breakage.

5. Always turn off the power source and wait for the tool to come to a complete stop before removing it from the workpiece.

In Conclusion

The Cogsdill deburring tool is an indispensable tool for any manufacturing or metalworking operation. Its precision, efficiency, and versatility make it an ideal choice for smoothing out rough edges, removing burrs, and improving overall product quality. By following proper safety procedures and using the right tool for the job, you can achieve outstanding results with ease.

References:

https://en.wikipedia.org/wiki/Deburring

https://www.cogsdill.com/deburring-tools/

https://www.thomasnet.com/articles/machinery-tools-accessories/types-of-deburring-tools/