When it comes to hydraulic systems, hose crimping tools are essential for creating a tight seal between the hose and fitting. But with so many options available in the market, choosing the right one can be overwhelming. That’s why we’ve put together this comprehensive guide to help you understand everything you need to know about hose crimping tools.

[h2]What is a Hose Crimping Tool?[/h2]

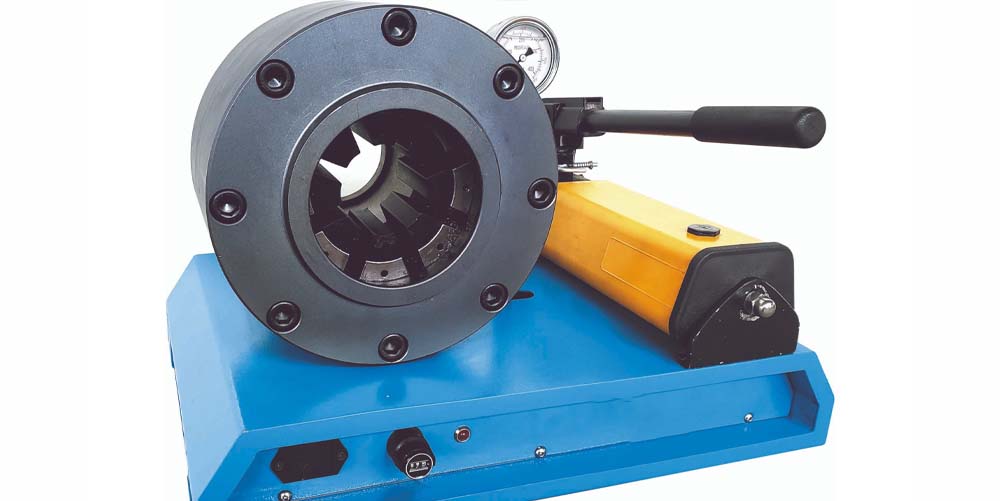

A hose crimping tool is a mechanical device that is used to compress and deform a metal collar around the end of a hydraulic hose. This process creates a permanent connection between the hose and fitting, ensuring a leak-free and secure joint. A good quality hose crimping tool should be easy to use, reliable, and produce consistent results every time.

[h2]Types of Hose Crimping Tools[/h2]

There are two main types of hose crimping tools available in the market:

1. Manual Hose Crimping Tool: As the name suggests, these tools require manual effort to create the crimp. They are usually less expensive than their hydraulic counterparts but require more physical effort and can only handle smaller diameter hoses.

2. Hydraulic Hose Crimping Tool: These tools use hydraulic pressure to create a crimp, making them easier and faster to use than manual tools. They can handle larger diameter hoses and are ideal for high volume applications. However, they are more expensive than manual tools.

[h2]Factors to Consider When Buying a Hose Crimping Tool[/h2]

When buying a hose crimping tool, there are several factors that you need to consider:

1. Hose Diameter: The diameter of the hose you will be working with will determine the type of tool you need. For smaller hoses (up to 1 inch), a manual crimping tool may suffice. For larger hoses, a hydraulic crimping tool is recommended.

2. Crimping Force: The crimping force required will depend on the type of hose and fitting you are using. Make sure to choose a tool that can generate enough force to create a secure connection.

3. Ease of Use: Look for a tool that is easy to operate and requires minimal setup time. A good quality tool should also produce consistent results every time.

4. Durability: Consider the materials used in the construction of the tool and look for features such as corrosion resistance and sturdy construction.

[h2]How to Use a Hose Crimping Tool[/h2]

Using a hose crimping tool is relatively straightforward, but it does require some practice to get it right. Here’s a step-by-step guide:

1. Choose the appropriate die set for your hose and fitting.

2. Insert the hose into the die set, making sure that it is fully inserted.

3. Place the collar over the end of the hose, ensuring that it is aligned with the die set.

4. Activate the crimping tool by either pumping the handle (for manual tools) or pressing a button (for hydraulic tools).

5. Release the pressure once you hear a “click” sound, indicating that the crimp is complete.

6. Inspect the crimped joint for any signs of leakage or damage.

[h2]Tips for Maintaining Your Hose Crimping Tool[/h2]

To ensure that your hose crimping tool remains in good condition and performs reliably, follow these tips:

1. Keep the tool clean and free from debris.

2. Lubricate moving parts regularly with a suitable lubricant.

3. Store the tool in a dry and cool place when not in use.

4. Replace worn or damaged parts immediately to prevent further damage to the tool.

[h2]Conclusion[/h2]

A hose crimping tool is a vital component of any hydraulic system, and choosing the right one can save you time, effort, and money in the long run. Consider the factors outlined in this guide when making your purchase, and follow our tips for using and maintaining your tool to ensure its longevity. With the right hose crimping tool in your arsenal, you can be confident that your hydraulic systems will perform reliably and efficiently.

[Reference: https://en.wikipedia.org/wiki/Crimping_(metalworking)]