Are you tired of struggling with inaccurate measurements and inconsistent layouts? Look no further than I beam layout tools! These innovative tools are designed to make your construction projects easier, faster, and more precise. In this article, we will explore the benefits of I beam layout tools and how they can revolutionize your construction process.

What are I Beam Layout Tools?

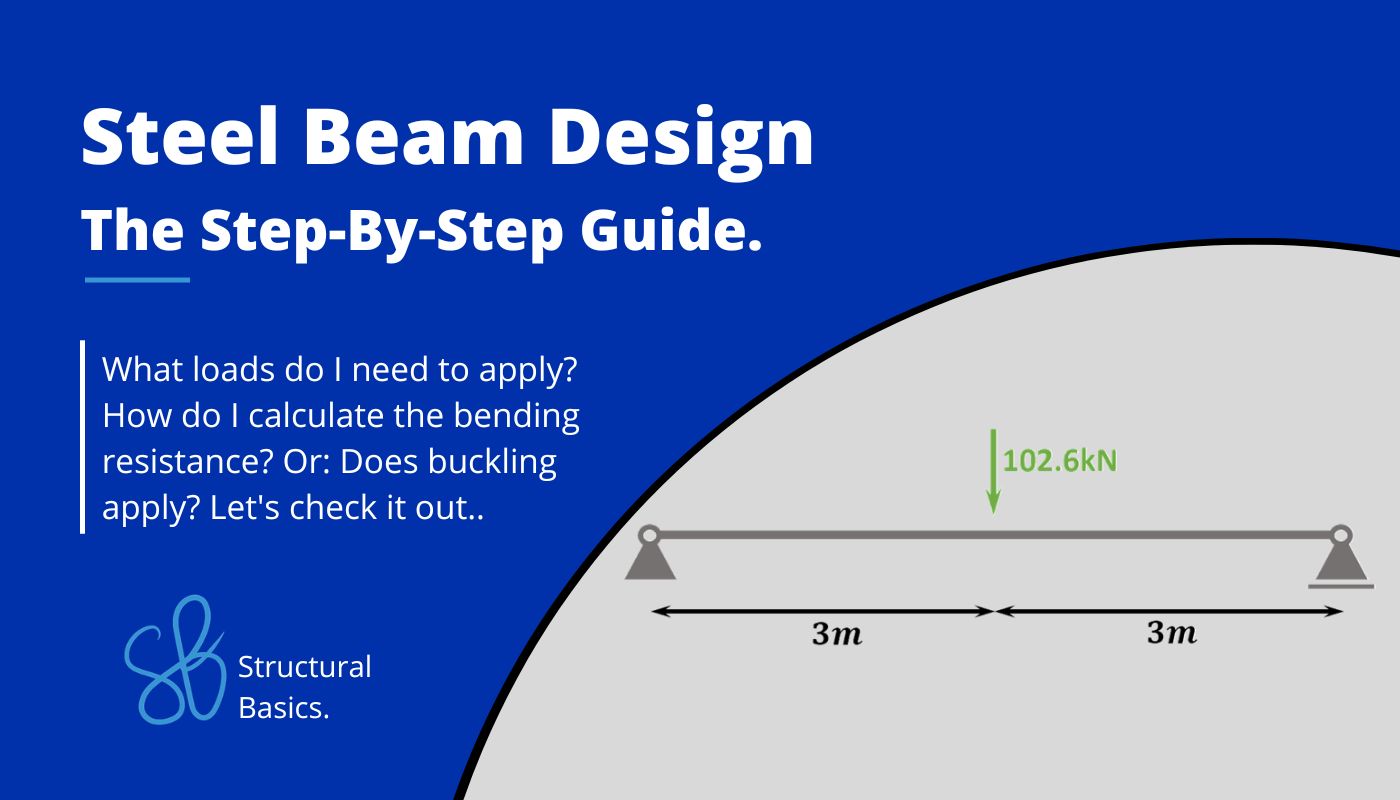

I beam layout tools are precision instruments used in construction projects to create accurate and efficient layouts. They consist of a laser level that projects a straight line onto a surface and a bracket that attaches to an I beam or other structural member. The bracket allows for easy adjustment of the laser level, ensuring that the line is perfectly horizontal or vertical.

Benefits of I Beam Layout Tools

1. Increased Efficiency

Using I beam layout tools can significantly increase your efficiency on the job site. By eliminating the need for manual measurements and calculations, you can complete layouts much faster than before.

2. Improved Accuracy

I beam layout tools allow for extremely precise measurements, ensuring that your layouts are accurate every time. This reduces the risk of errors and helps to prevent costly mistakes.

3. Better Safety

By reducing the amount of time spent manually measuring and calculating, you can spend more time focusing on safety precautions on the job site.

4. Versatile

I beam layout tools can be used for a wide variety of construction projects, including framing, drywall installation, electrical work, plumbing, and more.

Types of I Beam Layout Tools

1. Laser Levels

Laser levels are essential components of I beam layout tools. They project a straight line onto a surface for precise measurement and alignment.

2. Brackets

Brackets hold the laser level in place and attach to an I beam or other structural member. They allow for easy adjustments to ensure perfect alignment.

3. Tripods

Tripods provide a stable base for the laser level and bracket, ensuring that they remain in place during use.

How to Use I Beam Layout Tools

1. Attach the Bracket

Attach the bracket to the I beam or other structural member using the provided clamps.

2. Adjust the Laser Level

Adjust the laser level until it projects a straight line onto the surface you are working on. Use the adjustment knobs to ensure perfect alignment.

3. Secure the Tripod

Place the tripod on a stable surface and secure it in place. Attach the bracket and laser level to the tripod.

4. Complete Your Layout

Use the laser level to create precise measurements and layouts for your construction project.

Tips for Using I Beam Layout Tools

1. Take Your Time

I beam layout tools require precision and accuracy. Take your time and make sure that everything is aligned correctly before proceeding with your project.

2. Use a Level Surface

Make sure that your tripod is placed on a level surface to ensure that your measurements are accurate.

3. Keep Your Tools in Good Condition

Regularly clean and maintain your I beam layout tools to ensure that they continue to function properly.

Conclusion

I beam layout tools are essential components of any construction project. They provide increased efficiency, improved accuracy, better safety, and versatility for a wide variety of projects. By using these innovative tools, you can save time, reduce errors, and complete projects more efficiently than ever before.

References:

https://en.wikipedia.org/wiki/Laser_level

https://www.lowes.com/n/buying-guide/laser-level-buying-guide