Are you in the market for metal spinning tools? With so many options available, it can be overwhelming to choose the right tools for your project. However, with the right knowledge and guidance, you can make an informed decision that will help you achieve success in your metal spinning endeavors.

In this article, we will explore the different types of metal spinning tools available on the market, as well as their features and benefits. We will also provide tips on how to choose the right tools based on your specific needs and preferences.

So let’s dive in and discover everything you need to know about metal spinning tools!

[h2]What Are Metal Spinning Tools?[/h2]

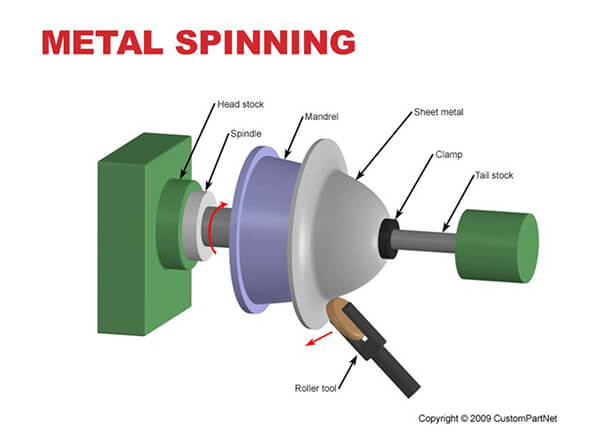

Metal spinning is a process that involves shaping a piece of metal into a desired shape using a lathe and specialized tools. These tools are designed to work with various metals, including aluminum, brass, copper, stainless steel, and more.

Metal spinning tools come in different shapes and sizes depending on the type of job they are intended for. They can be made of different materials such as carbide or high-speed steel. The most common types of metal spinning tools include:

[h2]1. Mandrels[/h2]

Mandrels are one of the most important metal spinning tools. They are used to support the workpiece while it is being spun on a lathe. Mandrels come in different shapes and sizes depending on the type of job they are intended for.

The most common types of mandrels include:

– Straight mandrels: These are used for simple shapes like cylinders or cones.

– Tapered mandrels: These are used for creating tapered shapes like bowls or vases.

– Stepped mandrels: These are used for creating stepped shapes like lampshades or funnels.

[h2]2. Chucks[/h2]

Chucks are used to hold the mandrel in place while it is being spun on a lathe. They come in different types and sizes, including:

– Scroll chucks: These are used for holding small to medium-sized workpieces.

– Independent chucks: These are used for holding large or irregularly shaped workpieces.

– Collet chucks: These are used for holding small workpieces with precision.

[h2]3. Cutting Tools[/h2]

Cutting tools are used to remove material from the workpiece during the metal spinning process. They come in different shapes and sizes depending on the type of job they are intended for.

The most common types of cutting tools include:

– Knives: These are used for cutting thin materials like foil or sheet metal.

– Shears: These are used for cutting thicker materials like brass or copper.

– Scissors: These are used for cutting curved shapes like circles or ovals.

[h2]4. Rollers[/h2]

Rollers are used to shape the workpiece by applying pressure to it during the metal spinning process. They come in different shapes and sizes depending on the type of job they are intended for.

The most common types of rollers include:

– Flat rollers: These are used for shaping flat sheets of metal into cylindrical shapes.

– Round rollers: These are used for shaping round objects like bowls or vases.

– Beading rollers: These are used for creating decorative edges on metal objects.

[h2]5. Burnishing Tools[/h2]

Burnishing tools are used to polish the surface of the workpiece after it has been shaped using other metal spinning tools. They come in different shapes and sizes depending on the type of job they are intended for.

The most common types of burnishing tools include:

– Abrasive pads: These are used for removing scratches or imperfections from the surface of the workpiece.

– Burnishing wheels: These are used for polishing the surface of the workpiece to a high shine.

– Wire brushes: These are used for cleaning and preparing the surface of the workpiece before burnishing.

[h2]Choosing the Right Metal Spinning Tools[/h2]

Now that you know about the different types of metal spinning tools available on the market, it’s time to choose the right tools for your project. Here are some tips to help you make an informed decision:

[h2]1. Consider Your Budget[/h2]

Metal spinning tools can be expensive, so it’s important to consider your budget before making a purchase. Determine how much you are willing to spend and look for tools that fit within your price range.

[h2]2. Consider Your Skill Level[/h2]

If you are new to metal spinning, you may want to start with basic tools like straight mandrels and scroll chucks. As you gain more experience, you can invest in more advanced tools like tapered mandrels or independent chucks.

[h2]3. Consider Your Project Requirements[/h2]

Think about what type of metal spinning project you will be working on and choose tools that are appropriate for that project. For example, if you are creating a bowl, you will need round rollers and shears.

[h2]4. Consider the Materials You Will Be Working With[/h2]

Different metal spinning tools are designed to work with different types of metals. Make sure the tools you choose are appropriate for the materials you will be working with.

[h2]Conclusion[/h2]

Metal spinning is a fascinating process that requires specialized tools to achieve success. By choosing the right metal spinning tools based on your specific needs and preferences, you can create beautiful and functional objects from various metals.

We hope this guide has helped you understand the different types of metal spinning tools available on the market and how to choose the right ones for your project. Happy spinning!

[wiki]https://en.wikipedia.org/wiki/Metal_spinning[/wiki]