Are you tired of dealing with machinery that doesn’t work the way it should? Do you find yourself constantly adjusting parts or trying to fix errors in your equipment? If so, then a shim tool may be just what you need to make things run more smoothly.

In this article, we’ll explore everything you need to know about shim tools, including their uses, benefits, and how to choose the right one for your needs. So grab a cup of coffee and get ready to learn!

What is a Shim Tool?

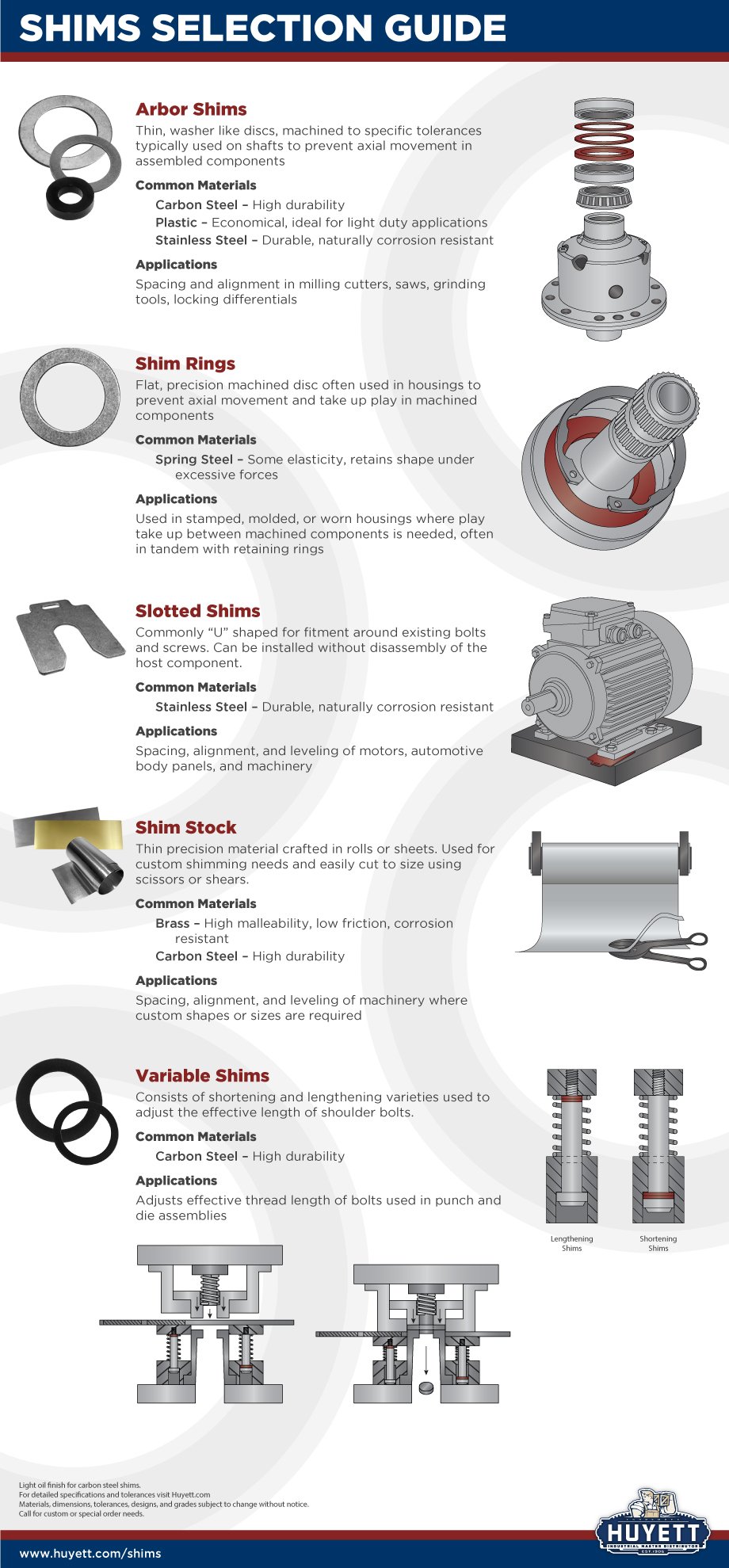

A shim tool is a device used to adjust the height or spacing between two objects. It’s essentially a thin piece of metal or plastic that can be inserted between two parts to create a tighter fit or remove any gaps. Shim tools come in various shapes and sizes, depending on the specific application they’re designed for.

Uses of Shim Tools

Shim tools are incredibly versatile and have many different uses across a range of industries. Some of the most common applications include:

1. Machinery adjustment: Shim tools are often used in manufacturing plants to adjust the height of machine parts or eliminate any gaps between them. This ensures that machines run smoothly and reduces the risk of wear and tear over time.

2. Automotive repair: Mechanics use shim tools to adjust the clearance between engine components, such as valves and pistons. This helps to improve engine performance and reduce emissions.

3. Construction: Builders use shim tools to level uneven surfaces or create tight fits between materials such as wood or metal.

4. Electrical work: Electricians use shim tools to adjust the positioning of electrical components or ensure that wires are properly spaced and secured.

Benefits of Shim Tools

So why should you consider using a shim tool in your work? Here are just a few benefits:

1. Improved accuracy: Shim tools allow for precise adjustments, ensuring that components fit together perfectly and reducing the risk of errors or malfunctions.

2. Cost-effective: Shim tools are relatively inexpensive compared to other machinery adjustment tools, making them a cost-effective option for many businesses.

3. Time-saving: By using a shim tool to make adjustments, you can save time and avoid having to disassemble machinery or materials completely.

4. Versatility: Shim tools come in various sizes and shapes, making them suitable for a range of applications across different industries.

Choosing the Right Shim Tool

When it comes to choosing a shim tool, there are a few things to consider:

1. Material: Shim tools can be made from metal or plastic, with each material offering its own benefits and drawbacks. Metal shims tend to be more durable and long-lasting but may cause damage if not used correctly. Plastic shims are lightweight and easy to work with but may not be as strong as their metal counterparts.

2. Size: Make sure you choose the right size shim tool for your needs. Too small, and it won’t provide the necessary support; too large, and it may interfere with other components.

3. Thickness: The thickness of your shim tool will determine how much space it can fill between two parts. Thicker shims offer more support but may require additional adjustments to achieve the desired fit.

Conclusion

Shim tools are an essential part of many industries, providing precise adjustments that improve accuracy, save time, and reduce costs. Whether you’re working in manufacturing, construction, or automotive repair, there’s bound to be a shim tool that meets your needs.

Remember to choose the right size and material for your application, and always use caution when making adjustments with shim tools. With these tips in mind, you’ll be well on your way to achieving optimal performance and efficiency in your work!

References:

– https://en.wikipedia.org/wiki/Shim_(spacer)

– https://www.mcmaster.com/shim-stock

– https://www.engineeringtoolbox.com/shim-types-d_1407.html