If you’re in the market for a thread tool for your lathe, you may be feeling overwhelmed by all of the options available. It can be difficult to know which one is right for your specific needs. In this article, we’ll explore everything you need to know about thread tools for lathes, including what they are, how they work, and what to look for when choosing the right one.

What is a Thread Tool for Lathe?

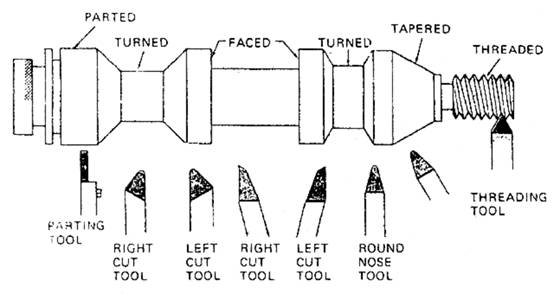

A thread tool for lathe is a cutting tool used to create threads on a workpiece. It is typically made from high-speed steel or carbide and is designed to fit into the tool holder on a lathe. Thread tools come in a variety of shapes and sizes, each with its own specific purpose.

How Does a Thread Tool Work?

A thread tool works by cutting into the workpiece as it rotates on the lathe. The tool creates spiraling grooves that run along the length of the workpiece. These grooves form the threads that allow nuts and bolts to screw onto the workpiece.

What Types of Thread Tools are Available?

There are several types of thread tools available, each designed for specific applications. Here’s an overview of some of the most common types:

1. External Thread Tools – These tools are used to cut threads on the outside of a workpiece.

2. Internal Thread Tools – These tools are used to cut threads on the inside of a workpiece.

3. Single Point Tools – These tools have only one cutting edge and are used for general-purpose threading.

4. Multi-Point Tools – These tools have multiple cutting edges and are used for high-production threading.

5. Forming Tools – These tools are used to create threads by deforming rather than cutting the material.

6. Grooving Tools – These tools are used to cut grooves for O-rings and other sealing devices.

What to Consider When Choosing a Thread Tool

Choosing the right thread tool for your lathe can be a daunting task. Here are some factors to consider:

1. Material – The material you’re working with will determine the type of thread tool you need. Soft materials like aluminum require a different type of tool than hard materials like steel.

2. Thread Pitch – The pitch of the thread determines how many threads per inch there are. Different thread pitches require different types of tools.

3. Cutting Speed – The cutting speed of the tool must match the material being worked on to prevent damage to the workpiece or tool.

4. Tool Geometry – The shape and angle of the cutting edge affect the quality of the threads produced.

5. Tool Coating – Coatings like titanium nitride can increase tool life and improve performance.

Conclusion

Choosing the right thread tool for your lathe is crucial to achieving high-quality, accurate threads on your workpiece. By considering factors like material, thread pitch, cutting speed, tool geometry, and coating, you can ensure that you select the best tool for your specific needs.

References:

– https://en.wikipedia.org/wiki/Threading_(manufacturing)

– https://www.machiningcloud.com/articles/choosing-right-threading-tool/

– https://www.thomasnet.com/articles/custom-manufacturing-fabricating/thread-cutting-tools-guide/