If you’re looking for a versatile, reliable, and cost-effective material for your projects, tooling foam might just be the answer you’ve been searching for. Tooling foam has become an increasingly popular choice in recent years due to its unique properties that make it ideal for a wide range of applications.

In this comprehensive guide, we’ll take a closer look at what tooling foam is, its benefits and uses, and how you can incorporate it into your own projects. With this knowledge, you’ll be able to make informed decisions about whether or not tooling foam is the right choice for your next project.

What Is Tooling Foam?

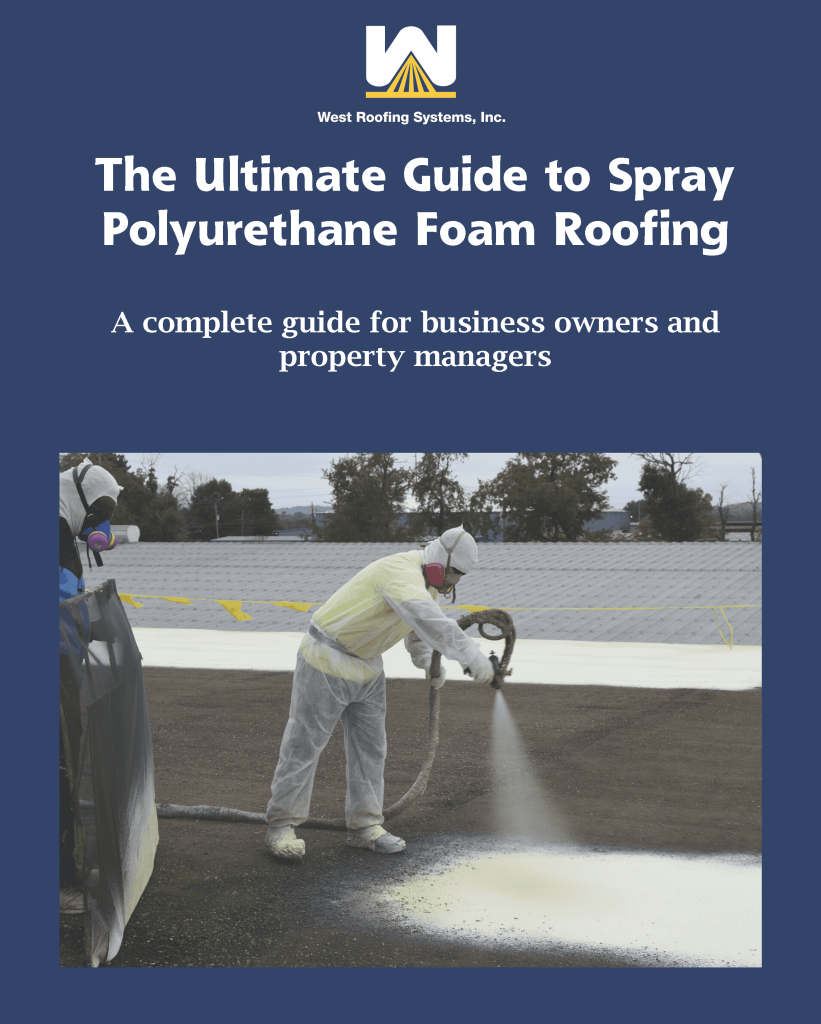

Tooling foam is a type of rigid foam that is typically made from polyurethane. It’s often used as a replacement for traditional materials such as wood or metal because it’s lightweight, easy to work with, and less expensive. Tooling foam comes in various densities ranging from low-density (1-2 lb/ft3) to high-density (20-30 lb/ft3), which gives it a wide range of uses.

Benefits of Using Tooling Foam

There are many benefits to using tooling foam in your projects. Here are some of the most significant advantages:

1. Lightweight – One of the primary benefits of using tooling foam is that it’s incredibly lightweight. This makes it ideal for applications where weight is a concern, such as aerospace or automotive industries.

2. Easy to Shape – Tooling foam can be easily shaped using standard woodworking tools. This allows you to create complex shapes and designs without needing specialized equipment or skills.

3. Uniform Density – Unlike natural materials such as wood or metal, tooling foam has a uniform density throughout the entire material. This means that there are no weak spots or variations in density that can affect the performance of the final product.

4. Cost-Effective – Tooling foam is less expensive than many traditional materials, making it an affordable option for many projects.

5. Resistant to Moisture – Tooling foam is resistant to moisture, which means that it won’t warp or degrade over time when exposed to water or humidity.

Uses of Tooling Foam

Tooling foam has a wide range of uses in various industries. Here are some of the most common applications:

1. Prototyping – Tooling foam is often used in prototyping because it’s easy to work with and can be quickly shaped into complex designs.

2. Molds – Tooling foam is commonly used to create molds for fiberglass or other composite materials.

3. Props and Displays – The lightweight nature of tooling foam makes it ideal for creating props and displays for the film and theater industry.

4. Aerospace and Automotive Industries – Tooling foam is often used in the aerospace and automotive industries as a lightweight alternative to traditional materials such as metal or wood.

5. Architectural Models – Architects often use tooling foam to create detailed models of buildings due to its lightweight nature and ease of shaping.

Working with Tooling Foam

Working with tooling foam requires some specialized knowledge and equipment, but it’s generally easy to work with once you get the hang of it. Here are some tips for working with tooling foam:

1. Use Appropriate Safety Equipment – When cutting tooling foam, be sure to wear eye protection and a mask to avoid inhaling any dust particles.

2. Choose the Right Density – The density of your tooling foam will depend on the application you’re using it for. Be sure to choose the appropriate density for your project.

3. Use Sharp Tools – Because tooling foam is relatively soft, it’s essential to use sharp tools when cutting or shaping it.

4. Sand Smoothly – When sanding tooling foam, use a light touch and work slowly to avoid creating rough or uneven surfaces.

5. Use Adhesives Wisely – Tooling foam can be glued together using a variety of adhesives, but it’s essential to choose the right adhesive for your project and use it sparingly to avoid warping or distorting the material.

Conclusion

Tooling foam is a versatile and cost-effective material that has many benefits and uses. Whether you’re working in the aerospace industry, creating architectural models, or building props for film and theater, tooling foam is an excellent choice that can save you time and money while still delivering high-quality results.

If you’re interested in learning more about tooling foam or incorporating it into your next project, be sure to do your research, choose the appropriate density for your application, and work carefully to achieve the best possible results.

References

1. “Polyurethane Foam,” Wikipedia.org.

2. “Tooling Foam: What It Is and How to Use It,” AcmePlastics.com.

3. “The Benefits of Using Polyurethane Foam,” UniversalFoam.com.

4. “Working with Rigid Foam Insulation,” FineHomebuilding.com.

5. “Tips for Cutting Rigid Foam Insulation,” TheSpruce.com.