As the world becomes increasingly reliant on technology, the demand for precision metal products continues to surge. From automobiles to medical devices, there is an enormous need for high-quality metal parts that are manufactured with accuracy and precision. And when it comes to precision metal stamping techniques, Wiegel Tool Works is a name that stands out from the rest.

Established in 1941, Wiegel Tool Works has been providing top-notch precision metal stamping solutions for over 80 years. With a team of highly skilled engineers and technicians, they specialize in creating custom metal parts using state-of-the-art technology and innovative techniques. In this article, we’ll take a deep dive into how Wiegel Tool Works operates and explore their unique approach to manufacturing high-quality metal parts.

What Is Precision Metal Stamping?

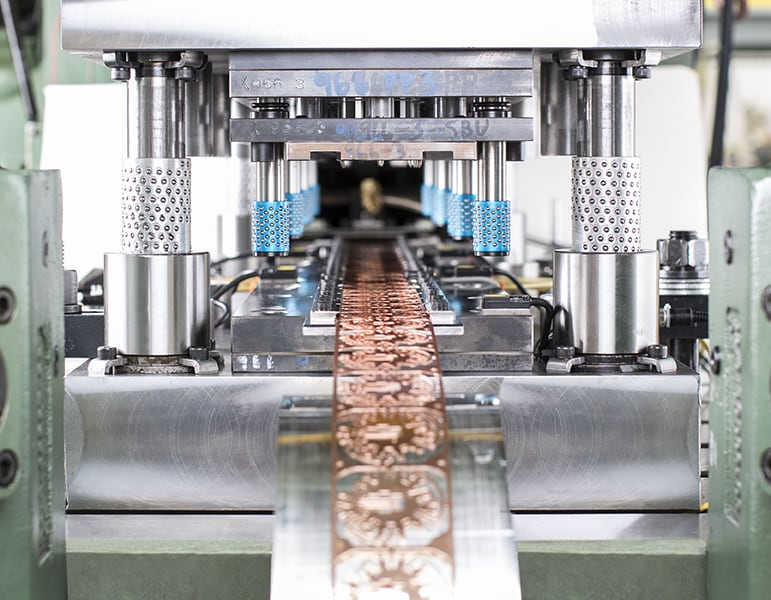

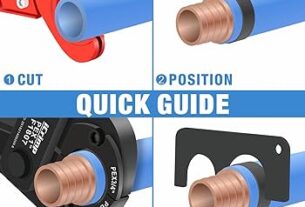

Before we delve deeper into Wiegel Tool Works and their methods, let’s first define what precision metal stamping is. At its core, precision metal stamping involves creating custom metal parts by shaping sheet metal through a series of processes such as punching, blanking, bending, and forming. These processes are carried out using specialized machines that use dies or molds to shape the sheet metal into the desired form.

The final product can be used in a variety of industries such as automotive, medical, aerospace, electronics, and more. Precision metal stamping is particularly useful for creating intricate parts that require high levels of accuracy and consistency.

How Does Wiegel Tool Works Operate?

Wiegel Tool Works prides itself on being at the forefront of precision metal stamping technology. They use cutting-edge equipment and software to ensure that their clients receive nothing but the best quality products.

One unique aspect of Wiegel Tool Works’ approach is their focus on collaboration with customers. They work closely with clients to understand their specific needs and create customized solutions that meet those needs. This includes everything from creating 3D models of the final product to using simulation software to test and optimize the manufacturing process.

Wiegel Tool Works also places a strong emphasis on quality control. They use advanced inspection equipment such as coordinate measuring machines (CMMs) and optical comparators to ensure that each part meets strict specifications.

The Wiegel Tool Works Difference

So what sets Wiegel Tool Works apart from other precision metal stamping companies? For one, they have a long history of excellence in the industry. Since their founding in 1941, they have maintained a commitment to quality and innovation that has allowed them to stay ahead of the curve.

Another key differentiator is their investment in technology. Wiegel Tool Works uses the latest software and equipment to ensure that they are delivering the best possible products to clients. This commitment to staying up-to-date with the latest advancements in precision metal stamping technology allows them to provide unique solutions for even the most complex projects.

Finally, Wiegel Tool Works’ focus on collaboration and customization is a major factor in their success. By working closely with clients, they are able to create tailored solutions that meet specific needs. This approach has helped them build a reputation as a trusted partner for businesses across industries.

Conclusion

Precision metal stamping is a critical component of modern manufacturing, and Wiegel Tool Works is at the forefront of this field. With a commitment to quality, innovation, and collaboration, they have established themselves as a leader in the industry.

Whether you’re looking for high-quality metal parts for your business or simply want to learn more about precision metal stamping techniques, Wiegel Tool Works is an excellent resource. With decades of experience and a team of highly skilled professionals, they are well-equipped to handle any project with precision and efficiency.

References:

– Wiegel Tool Works website: https://www.wiegeltoolworks.com/

– Precision Metalforming Association: https://www.pma.org/

– Metalforming Magazine: https://www.metalformingmagazine.com/