If you’re in the metal fabrication industry, you know how important it is to have the right tools. One of the most essential pieces of equipment in your workshop is a press brake machine, and having quality tooling is crucial for achieving accurate bends and precise results. That’s why Wilson Tool International has become one of the most trusted names in press brake tooling.

In this guide, we’ll take an in-depth look at Wilson Press Brake Tooling, including their history, product offerings, and how to choose the right tools for your specific application. Whether you’re a seasoned veteran or just getting started in metal fabrication, this article will provide valuable insights into optimizing your press brake operations.

History of Wilson Tool International

Wilson Tool International has been a leader in the metalworking industry since 1966 when founder Jim Wilson started the company as a manufacturer of punch and die components. Over the years, Wilson Tool has expanded its product line to include a wide range of tooling solutions for various metalworking applications, including bending, punching, stamping, and more.

Today, Wilson Tool International operates out of several locations worldwide and serves customers across multiple industries, from aerospace to automotive and beyond. Their commitment to innovation and customer satisfaction has made them one of the most respected names in the industry.

Product Offerings

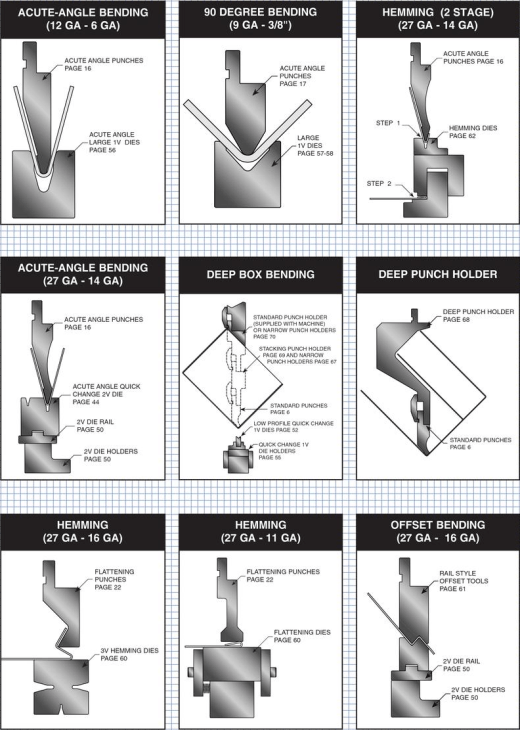

When it comes to press brake tooling, Wilson Tool offers an extensive lineup of products designed to meet any need or application. Here are some of their most popular offerings:

1. V-Series

The V-Series is Wilson Tool’s flagship line of press brake tooling. These tools are compatible with most machines on the market and offer outstanding durability and precision. They come in a variety of sizes and configurations to suit different sheet thicknesses and bend angles.

2. HP Series

The HP Series is designed for high-performance applications and is ideal for working with thicker materials. These tools feature a unique design that reduces deformation and improves accuracy, resulting in cleaner bends and fewer errors.

3. Precision Ground Tooling

For the most demanding applications, Wilson Tool offers precision ground tooling that is machined to exacting tolerances. These tools are designed for use with high-strength materials and can handle even the most complex bending operations.

Choosing the Right Wilson Press Brake Tooling

With so many options available, it can be challenging to choose the right press brake tooling for your specific application. Here are some factors to consider when selecting Wilson Tool products:

1. Material Type and Thickness

The type of material you’re working with will play a significant role in determining which tooling is best suited for your needs. Thicker materials typically require more robust tools, while thinner sheets may benefit from more delicate tooling.

2. Bend Angle

The angle at which you need to bend your material will also impact your choice of tooling. Some tools are designed specifically for acute or obtuse angles, while others can handle a wide range of bend angles.

3. Machine Compatibility

Not all press brake machines are created equal, so it’s essential to ensure that the tools you choose are compatible with your machine’s specifications. Wilson Tool offers a wide range of tooling that is compatible with most popular brands and models.

4. Production Volume

If you’re working with high-volume production runs, you’ll want to choose durable tooling that can withstand heavy use over time. Conversely, if you’re only doing occasional small-batch runs, you may be able to get away with less expensive or less robust tooling.

5. Budget

Finally, budget is always a consideration when choosing any piece of equipment or tooling solution. Wilson Tool offers a range of products at different price points, so it’s essential to balance your needs with your budget when making your selection.

Final Thoughts

Wilson Press Brake Tooling is an excellent choice for any metal fabricator looking to optimize their press brake operations. With a wide range of high-quality products and a commitment to innovation and customer satisfaction, Wilson Tool International has earned its reputation as one of the industry’s most trusted names.

By considering factors such as material type and thickness, bend angle, machine compatibility, production volume, and budget, you can make an informed decision when selecting Wilson Tool products. Whether you’re working with thin aluminum sheets or thick steel plates, there’s a Wilson tool that can help you achieve accurate bends and precise results.

References:

1. https://www.wilsontool.com/en-US/Products/Press-Brake-Tooling

2. https://www.wilsontool.com/en-US/About-Us/Our-History