As an engine owner or mechanic, you know that proper engine maintenance is essential to ensure its longevity and efficiency. One of the critical aspects of maintaining engines is valve lash adjustment. To achieve perfect valve clearance, you need the right tool – a valve lash tool.

In this article, we will discuss everything you need to know about valve lash tools. From what they are, how they work, their types, and how to choose the right one for your needs. So, let’s dive in!

What is a Valve Lash Tool?

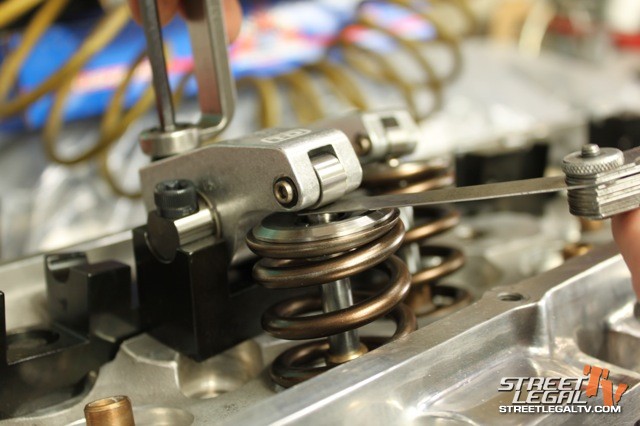

A valve lash tool is a device used for adjusting the clearance between the camshaft and the valve stem in an internal combustion engine. The term “lash” refers to the gap between the tappet and the valve stem when the cam lobe is not in contact with the tappet.

The valve lash needs to be adjusted periodically to maintain optimal engine performance. If left unadjusted, it can cause problems such as reduced power output, increased fuel consumption, and even engine failure.

Types of Valve Lash Tools

There are two main types of valve lash tools – feeler gauges and dial indicators.

Feeler gauge: A feeler gauge consists of a set of metal blades of different thicknesses. They are inserted between the cam lobe and the tappet to measure the gap between them. The correct blade thickness is selected based on manufacturer specifications.

Dial indicator: A dial indicator measures the actual lift of the cam lobe as it pushes against the tappet. It provides more precise measurements than a feeler gauge.

How Does a Valve Lash Tool Work?

A valve lash tool works by measuring the clearance between the camshaft and tappet or rocker arm. The clearance measured is then compared to manufacturer specifications, and adjustments are made using shims or adjustable pushrods.

To adjust the valve lash, the engine needs to be at top dead center (TDC) on the compression stroke. The valve cover is removed, and the rocker arms are loosened. The valve lash tool is then used to measure the clearance between the cam lobe and tappet or rocker arm.

If adjustments are needed, shims or adjustable pushrods are used to achieve the correct valve lash. Once adjusted, the rocker arms are tightened to manufacturer specifications.

How to Choose the Right Valve Lash Tool?

Choosing the right valve lash tool depends on several factors such as engine type, personal preference, and budget. Here are some tips for choosing the right valve lash tool:

1. Compatibility: Make sure that the valve lash tool you choose is compatible with your engine type. Different engines have different specifications, so it’s essential to choose a tool that matches your engine.

2. Type of Tool: Consider which type of valve lash tool suits your needs – feeler gauge or dial indicator. Dial indicators provide more precise measurements but are also more expensive than feeler gauges.

3. Quality: Choose a valve lash tool made from high-quality materials that can withstand frequent use and last for a long time.

4. Budget: Set a budget based on how often you will use the tool and what features you need.

Conclusion

A valve lash tool is an essential device for maintaining optimal engine performance. By adjusting the clearance between the camshaft and tappet or rocker arm using a valve lash tool, you can prevent problems such as reduced power output, increased fuel consumption, and even engine failure.

When choosing a valve lash tool, consider factors such as compatibility, type of tool, quality, and budget. With the right tool in hand and proper maintenance, your engine will run smoothly for years to come!

References:

Valve Lash Adjustment – Engine Builder Magazine

What is Valve Lash? – Speedway Motors

Valve Lash Adjustment – Hot Rod Network